🔍 What Does "Pulses per Revolution" Mean?

In a closed-loop stepper system, the encoder provides feedback about motor position. The PPR value represents how many distinct signal pulses are generated during one full rotation of the motor shaft.

-

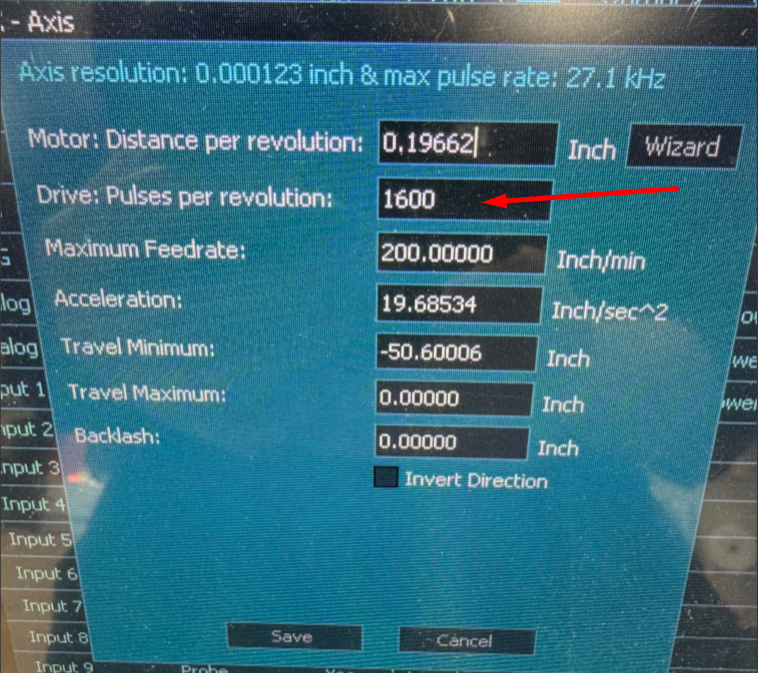

1600 PPR = 1600 pulses per full revolution

-

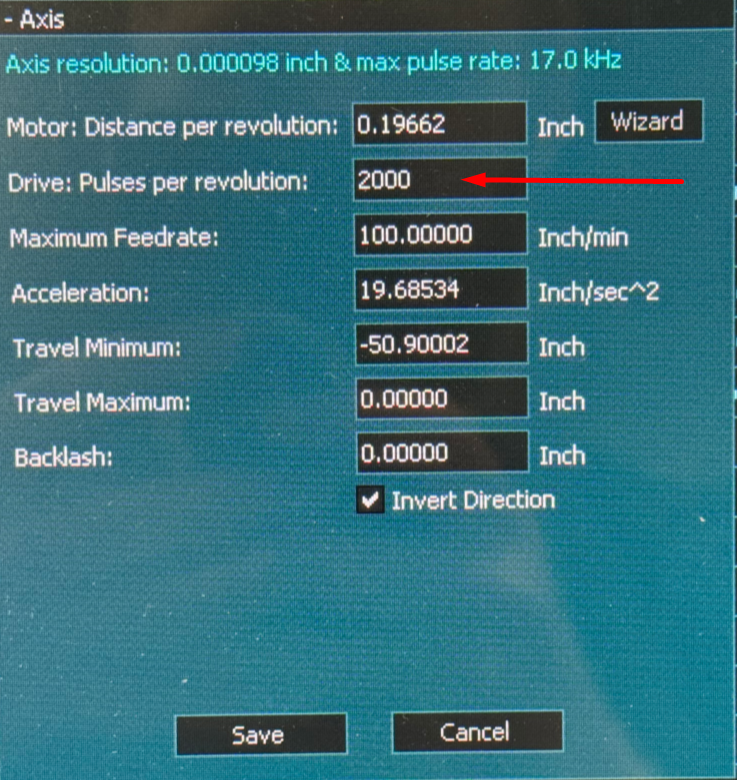

2000 PPR = 2000 pulses per full revolution

This directly affects the resolution of feedback the controller receives and how finely it can track or adjust the motor position.

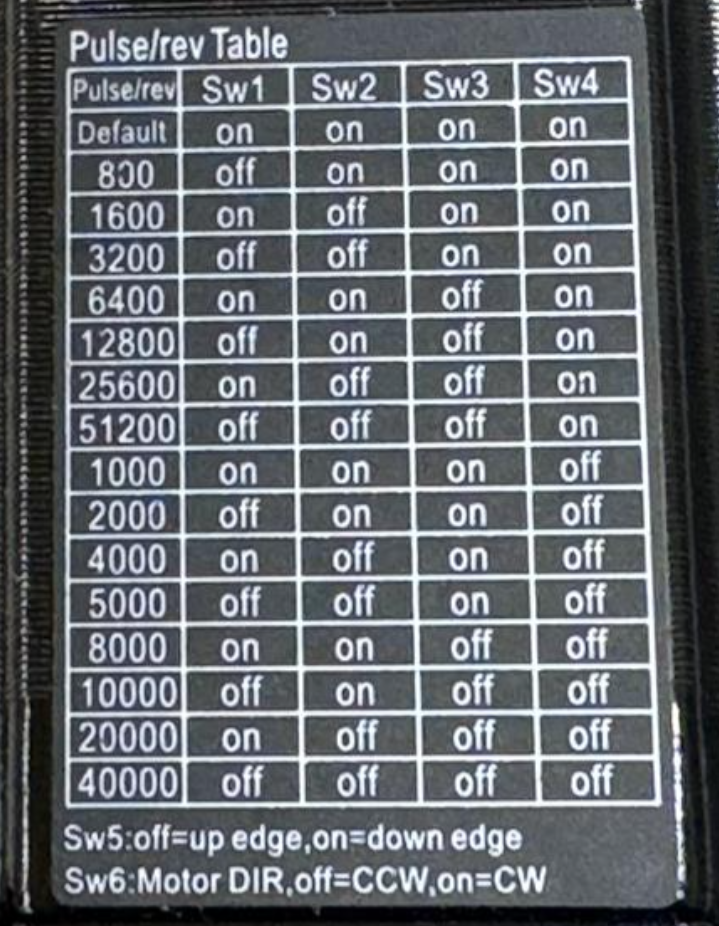

On the side of the motor you may find a chart like this:

It defines how the dip-switch positions should be configured based on how you're controller matches.

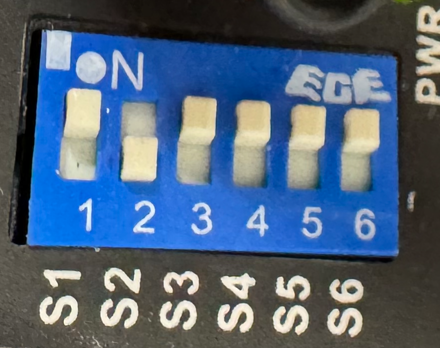

The steppers first four switches can be set to any combination as described by this table.

SW6 relate to the "Invert Direction" and act as an physical inversion compared to the digital conversion checkbox within the controller.

1600 Pulse/rev

These dip-switch settings will correspond with this configuration in your controller:

2000 Pulse/rev

These dip-switch settings will correspond with this configuration in your controller:

Which to choose?

Choosing between 1600 pulses per revolution (PPR) and 2000 PPR for a closed-loop stepper motor configuration depends on several factors related to resolution, system responsiveness, and performance characteristics. Here’s a breakdown to help you understand the differences and make the right choice for your use case.

⚙️ Technical Differences

| Feature | 1600 PPR | 2000 PPR |

|---|---|---|

| Resolution | Lower | Higher |

| Pulse Frequency at same RPM | Lower | Higher |

| Feedback Responsiveness | Slightly less precise | Slightly more precise |

| Controller Load | Lower CPU load | Slightly higher CPU load |

| Interference Sensitivity | Lower (generally) | Higher due to faster signals |

| Torque Ripple Smoothing | Good | Slightly better |

🔧 Why Choose 1600 PPR?

Advantages:

-

Lower frequency signal = less demand on controller and cabling

-

Good enough for most hobby CNC routers and machines using leadscrews or ballscrews with moderate pitch

-

Compatible with motion controllers or drives that might have trouble with high-speed encoder inputs

When to use:

-

If your machine doesn’t need extremely fine feedback resolution (e.g. wood routing, plastic cutting)

-

If your controller has limited encoder input frequency support

-

If you’re operating in an electrically noisy environment

🛠️ Why Choose 2000 PPR?

Advantages:

-

Finer position tracking per rotation, leading to potentially smoother motion

-

Better precision in error correction under dynamic load changes

-

Can reduce "hunting" behavior or oscillation around setpoints

When to use:

-

If your application demands high positional accuracy (e.g. aluminum cutting with small tools)

-

If your controller can handle the higher encoder pulse rate without errors

-

If you're running high-speed operations where fine feedback improves stability

🧠 Additional Considerations

1. Encoder to Driver Matching

Ensure your stepper driver and motion controller support the selected PPR value. Some drivers (especially cheaper or older ones) max out at ~200 kHz encoder input, which limits how fast a high-PPR encoder can rotate.

2. Mechanical Resolution

Higher PPR only benefits you if your mechanical system (screw pitch, gear reduction, etc.) and motion planner can take advantage of it. If you already have high microstepping or tight mechanical tolerances, 2000 PPR may compound benefits.

3. Electrical Noise

Higher pulse rates are more prone to degradation from EMI. Shielded cables and clean grounding become more important at 2000 PPR, especially on longer cable runs.

✅ Recommendation Summary

-

Default recommendation for hobby CNCs: Go with 1600 PPR for a balanced mix of performance, ease of setup, and compatibility.

-

Upgrade path: If a customer wants ultra-smooth performance or is doing fine engraving or metal work, offer 2000 PPR as an upgrade with a caveat about controller and EMI considerations.